Ubuchwepheshe bokusika wedayimane wedayimane buziwa nangokuthi ubuchwepheshe bokusika bokuhlanganisa. Kuyindlela yokusebenzisa i-electroopplating noma i-resin ehlanganisa indlela yedayimane ehlanganisiwe ebusweni be-wire yensimbi, i-diamond wire esebenza ngqo ebusweni be-silicon induku noma i-milicon ingot ukukhiqiza ukugaya, ukufeza umphumela wokusika. Ukusika kwe-diamond wire kunezimpawu zesivinini sokusika ngokushesha, ukunemba okuphezulu nokulahleka kwezinto ezibonakalayo eziphansi.

Njengamanje, imakethe ye-Crystal ye-Diamond Wire Ukusika isilayi sesilon we-silicon yamukelwa ngokuphelele, kodwa futhi ihlangabezane nenqubo yokuphromotha, phakathi kwayo iVelvet White yinkinga evame kakhulu. Ngenxa yalokhu, leli phepha ligxile ekutheni ungavimbela kanjani ukuncishiswa kwe-diamond wire monocrystalline we-silicon wafer velvet White White.

Inqubo yokuhlanza yedayimane yokusika isicingo i-monocrystalline silicon wafer ukususa i-silicon wafer osikwe yithuluzi lomshini we-wire saw nge-porte plate, susa umdweshu werabha, uhlanze i-silicon wafer. Imishini yokuhlanza ikakhulukazi umshini wokuhlanza owangaphambi kokuhlanza (umshini wokuhlanza) kanye nomshini wokuhlanza. Inqubo eyinhloko yokuhlanza yomshini wokuhlanza ngaphambi kokuhlanza yile: ukondla-isifutho-sokuhlanza sokuhlanza - ukuhlukunyezwa kwamanzi okuhlanza amanzi. Inqubo eyinhloko yokuhlanza yomshini wokuhlanza yilena: ukondla amanzi ahlanzekile okuhlanza amanzi acwebile-alkali ukugeza-ama-alkali acwebile - amanzi okuhlanza amanzi acwebile (kancane kancane) -Ukuphakamisa kancane

Umgomo we-velvet ye-velvet eyodwa ye-crystal

I-Moocrystalline Silicon Wafer isici sokugqwala kwe-anisotropic of monocrystalline we-silicon wafer. Umgomo wokuphendula yi-equation elandelayo yokusabela kwamakhemikhali:

Si + 2Nahoh + H2O = NA2SIO3 + 2h2 ↑

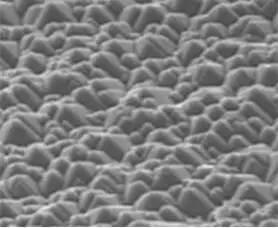

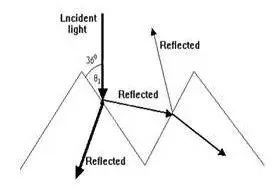

Empeleni, inqubo yokwakheka kwe-suede ithi: Isixazululo sooh sezinga elihlukile le-Crystal ebusweni obuhlukile, (100) isivinini sokugqwala esingaphezu kwe (111), ngakho (100), ngakho-ke (100), ngakho-ke (100) kuya ku-Anisotropic Corricoon, ekugcineni kwakhiwa ebusweni (111) Isigaxa esinezinhlangothi ezine, isakhiwo esithi "Pyramid" (njengoba kukhonjisiwe kuMfanekiso 1). Ngemuva kokuthi isakhiwo sakhiwe, lapho ukukhanya kuvinjezelwa emthambekeni wephiramidi endaweni ethile, ukukhanya kuzobonakala emthambekeni kwelinye i-angle , okungukuthi, umphumela wokukhanya okukhanyayo (bheka umfanekiso 2). Usayizi ongcono wesakhiwo kanye nokufana kwesakhiwo se- "Pyramid", umphumela we-trap osobala ngokwengeziwe, kanye nokwehla kokungena kobuso be-silicon wafer.

Umdwebo 1: I-Micromorphology of Monocrystalline Silicon wafer ngemuva kokukhiqizwa kwe-Alkali

Umdwebo 2: Umgomo Wesicupho Sokukhanya Kwesakhiwo se- "Pyramid"

Ukuhlaziywa kokumhlophe okukodwa kwe-crystal

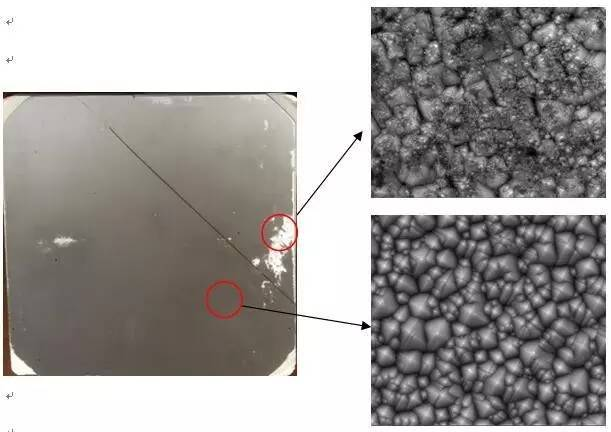

Ngokuhlola ama-microscope we-elektroni e-White Silicon Wafer, kwatholakala ukuthi i-Pyramidi Empstruction of the white wafer endaweni yale ndawo yasungulwa, kanti indawo yabonakala inezinsalela ze- "waxy", kuyilapho isakhiwo sePyramid se-suede Endaweni emhlophe ye-silicon wafer yasungulwa kangcono (bheka umfanekiso 3). Uma kunezinsalela ebusweni be-monocrystalline aillicon wafer, ingaphezulu le-sakhiwo lesakhiwo "uPyramid" usayizi wesakhiwo kanye nomphumela wendawo ojwayelekile futhi umphumela wendawo ejwayelekile akwanele, okuholela ekuvezeni komhlaba okujwayelekile kuphakeme kunendawo ejwayelekile, indawo enomthamo ophakeme ophakeme uma kuqhathaniswa nendawo ejwayelekile ekuboneni okubonakala njengomhlophe. Njengoba kungabonakala esimweni sokusatshalaliswa kwendawo emhlophe, akulona isimo esijwayelekile noma esijwayelekile endaweni enkulu, kodwa kuphela ezindaweni zasendaweni. Kufanele kube ukuthi ukungcoliswa kwendawo ebusweni be-silicon wafer akuhlanzwanga, noma isimo se-silicon wafer sibangelwa ukungcoliswa kwesibili.

Umdwebo 3: Ukuqhathaniswa kokungafani kwe-sussvet SucmCreature eVelvet White Silicon Wafers

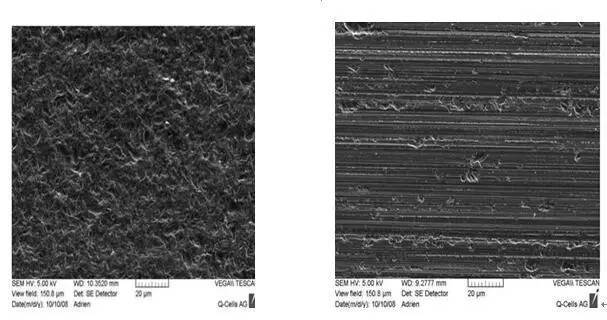

Ingaphezulu le-diamond wire ukusika i-silicon wafer ibushelelezi ngokwengeziwe futhi umonakalo mncane (njengoba kukhonjisiwe kuMfanekiso 4). Uma kuqhathaniswa nesigaxa se-silicon kasiticon, ijubane lokuphendula le-alkali kanye ne-diamond wire ukusika i-silicon wafer komhlaba lihamba kancane kunaleso se-Silicon Desiting Silicon wafer, ngakho-ke ithonya lezinsalela ze-velvet lisobala.

Umdwebo 4: (a) I-Micrograph ye-Mortar Cut Silicon Wafer (B) I-Micrograph ye-Diamond Wire Fine Cut Silicon Wafer

Umthombo oyinhloko we-Diamond wire-cut sile-cut silicon wafer super

. Uketshezi olusikiwe olunokusebenza okuhle kakhulu lunokumiswa okuhle, ukuhlakazeka kanye nekhono lokuhlanza elilula. Ama-surfactants ajwayele ukuba nezindawo ezingcono ze-hydrophilic, okulula ukuzihlanza kwinqubo yokuhlanza i-silicon wafer. Ukuthuthuka okuqhubekayo nokusakazwa kwalezi zithasiselo emanzini kuzokhiqiza inani elikhulu le-foam, okuholela ekunciphiseni kokugeleza okupholile, okuthinta ukusebenza okupholile, kanye nezinkinga ezimbi kakhulu, okuzothinta kakhulu ukusetshenziswa. Ngakho-ke, okupholile kuvame ukusetshenziswa nge-ejenti e-desouming. Ukuze uqinisekise ukusebenza kwe-desoamung, i-silicone yendabuko kanye ne-polyther imvamisa i-hydrophilic. I-solvent emanzini ilula kakhulu ku-adsorb futhi ihlale ebusweni be-silicon wafer ekuhlanzeni okulandelayo, okuholela enkingeni yendawo emhlophe. Futhi ayihambelani kahle nezakhi eziphambili ze-coolant, ngakho-ke, kufanele zenziwe ngezinto ezimbili, izingxenye eziphambili kanye nama-ejenti okufakelwa amanzi angezwe emanzini, ngokwesimo se-foam, ngokwesimo se-Foam, asikwazi ukulawula ubungako Ukusetshenziswa kanye Dosage of An Antifoam Agents, kungavumela kalula i-overdose yama-anoaming agents, okuholela ekukhuphukeni kwezinsalela ze-silicon wafer ebusweni, futhi kuphazamiseka kakhulu ukusebenza, ngenxa yentengo ephansi ye-ejenti Ngakho-ke, izinto eziningi zokupholisa kwasekhaya zonke zisebenzisa lolu hlelo lokusebenza; Enye i-coolont isebenzisa i-ejenti entsha ye-desouming, ingahambelana kahle nezakhi eziyinhloko, akukho okungeziwe, kungalawula ngempumelelo inani layo, kungavimba ngempumelelo ukusetshenziswa kwayo, izivivinyo zilula kakhulu, ziyinqubo efanelekile yokuhlanza, Izinsalela zingalawulwa emazingeni aphansi kakhulu, eJapan kanye nabakhiqizi bezilwane ezimbalwa bamukela lolu hlelo lokusebenza, ngenxa yezindleko zalo eziphakeme ezibonakalayo, inzuzo yayo yentengo ayibonakali.

. I-wire isiqalile ukusika ungqimba lwenjoloba kanye ne-resin plate, ngoba i-salicon rod glue kanye ne-resin board kunemikhiqizo yayo ye-epoxy, ngokuyisisekelo iphakathi kwama-55 no-95 ℃, uma i-resin Ipuleti liphansi, lingashisa kalula ngesikhathi senqubo yokusika futhi libenze lithambile futhi lincibilike, linamathiselwe kwintambo yensimbi kanye ne-silicon wafer ebusweni, noma ama-silicon wafers atholwa futhi Kunamabala nge-resin, wake wanamathiselwa, kunzima kakhulu ukugeza, kunzima kakhulu ukugeza, ukungcola okunjalo kwenzeka kakhulu eduze komphetho we-silicon wafer.

(3) I-Silicon Powder: Esezinhlelweni zokusika nge-diamond wire kuzokhiqiza i-silicon eningi, ngokuzisika, okuqukethwe okupholile kampompi kuzoba ngaphezulu kakhulu, lapho i-powder inkulu ngokwanele, izolandela i-silicon ebusweni, Futhi ukusika kwe-diamond wire usayizi we-silicon powder nosayizi kuholela kalula ku-adsorption e-silicon ebusweni, kwenze kube nzima ukuhlanza. Ngakho-ke, qinisekisa ukuvuselelwa nekhwalithi ye-coolant futhi unciphise okuqukethwe kwe-powder ku-coolant.

. Iqoqo eliphelele le-LINE, Ukusika okupholile nodaka kunomehluko omkhulu, ngakho-ke inqubo yokuhlanza ehambisanayo, imithamo ye-ejenti yokuhlanza, ifomula, njll. Umenzeli wokuhlanza uyisici esibalulekile, i-agent yohlobo lokuhlanza i-agent formula elisakhile, i-alkalinity ayifanele ukuhlanza ukugawulwa kwe-silicon walicon we-silicon, ukwakheka kwezinsalela ze-agent okuhlosiwe, futhi zithathe inqubo yokuhlanza. Njengoba kushiwo ngenhla, ukwakheka kwe-ejenti yokungcolisa akudingeki ekusikeni ngodaka.

.

Yehlisa inkinga yokwenza i-velvet hair white ivele iziphakamiso

.

(2) sebenzisa i-glue efanelekile ne-resin plate ukunciphisa ukungcoliswa kwe-silicon wafer;

(3) I-coolont ihlanganiswe namanzi ahlanzekile ukuqinisekisa ukuthi akukho ukungcola okulula okusele emanzini asetshenzisiwe;

(4) Ngaphezulu kwe-diamond wire cut silicon wafer, sebenzisa umsebenzi kanye nokuhlanza umphumela umenzeli ofanele wokuhlanza ofanele;

. Ngasikhathi sinye, futhi kungakhuphula ukuthuthuka kokushisa kwamanzi, ukugeleza nesikhathi ekuhlanzeni kwangaphambi kokugeza, ukuqinisekisa ukuthi i-silicon powder iyagezwa ngesikhathi

.

. (8) Enqubweni yokuhlanza ye-silicon wafer, isikhathi esiveziwe emoyeni singancishiswa ngangokunokwenzeka ukuvikela ukukhiqizwa kwezimbali ebusweni be-silicon wafer ebusweni.

.

. Umgomo wawo ufana nesixazululo sokuhlanza i-SC1 (esaziwa ngokuthi uketshezi 1) se-semiconductor ye-silicon wafer. Indlela yayo enkulu: Ifilimu le-oxidation esiteshini se-silicon wafer sakhiwa yi-oxidation of H2O2, esigcwaliswe nguNaoh, kanti nokugqwala nokugqwala kwenzeka kaninginingi. Ngakho-ke, izinhlayiya ezinamathiselwe ku-silicon powder, resin, i-metal, njll.) Futhi ziwela oketshebeni uketshezi lokuhlanza; Ngenxa ye-oxidation ye-H2O2, izinto eziphilayo endaweni ebukhali zibolile zibe yi-CO2, H2O futhi zisuswe. Le nqubo yokuhlanza ibilokhu abakhiqizi be-silicon wafer besebenzisa le nqubo ukucubungula ukuhlanzwa kwe-diamond wire ukusika i-monocrystalline we-silicon wafer, ama-saicon warferers e-batch batch batch of velvet White Inkinga Izikhalazo. Kukhona futhi abakhiqizi bebhethri basebenzise inqubo efanayo yokuhlanza kwangaphambi kwe-velvet, futhi balawula ngempumelelo ukubukeka kweVelvet White. Kuyabonakala ukuthi le nqubo yokuhlanza ingeziwe kwinqubo yokuhlanza i-silicon wafer ukususa izinsalela ze-silicon wafer ukuze ixazulule inkinga yezinwele ezimhlophe ekugcineni kwebhethri.

ukugcina

Njengamanje, ukusikwa kwentambo yedayimane sekuyibuchwepheshe obuphambili emkhakheni wokusika okukodwa, kepha ohlelweni lokukhuthaza inkinga ye-velvet yabakhiqizi be-velvet kube yinkinga ye-abicon wafer kanye nabakhiqizi bebhethri, okuholela kubakhiqizi bebhethri ku-diamond wire ukusika i-silicon I-Wafer inokumelana okuthile. Ngokuhlaziywa kokuqhathanisa kwendawo emhlophe, kubangelwa yizinsalela ngaphezulu kwe-silicon wafer. Ukuze uvikele kangcono inkinga ye-silicon wafer esitokisini, leli phepha lihlaziya imithombo engenzeka yokungcoliswa komhlaba we-silicon wafer, kanye neziphakamiso zokuthuthukisa kanye nezinyathelo zokukhiqiza. Ngokuya ngenombolo, isifunda kanye nokwakheka kwamabala amhlophe, izimbangela zingahlaziywa futhi zithuthukiswe. Kunconywa ikakhulukazi ukusebenzisa i-hydrogen peroxide + inqubo yokuhlanza i-alkali. Isipiliyoni esiphumelelayo sikufakazile ukuthi singavimba ngempumelelo inkinga yokusika ucingo lwe-silicon warfer ukwenza i-velvet mhlophe, ukuze kubhekwe ngumkhakha wemboni ojwayelekile nabakhiqizi.

Isikhathi Seposi: Meyi-30-2024